Pipe Bursting.

Pipe Bursting is an excavation free pipe replacement method used to replace old or damaged underground lines without having to dig up your entire property.

Instead of removing the old pipe, we break it apart underground using a specialized bursting head while simultaneously pulling a brand new, high-strength HDPE pipe through the same path. (High-Density Polyethylene, rust-resistant)

This is the most effective method for replacing old, failing pipes. On top of keeping your yard, driveway, and business intact and operational, you're guaranteed a lifetime-lasting upgrade that will leave you with peace of mind and stability.

(a) Bursting Head entering and replacing the old pipe by pulling through the new

Static and Pneumatic

Pipe Bursting systems generally fall into two main categories: Pneumatic & Static. To a simplicity, the difference comes down to the how that system breaks the old pipe, and what exactly powers it. Choosing the right method depends on a number of site-specific factors, including the condition and depth of the existing pipe, the type of replacement pipe, the soil type, and how much access is available. Experience, equipment, and risk all come into play when deciding which approach is best.

Pneumatic

Air Powered Force

Uses compressed air to drive a special hammer that breaks apart the old pipe, piece by piece.

Expander Creates Space

A cone-shaped expander pushes broken fragments and soil outward to make room for the new pipe.

Pulled Through by Winch

A cable keeps the tool centered and steadily pulls the new pipe into place.

Minimal Interruption

Once started, the process continues automatically until the new pipe is fully installed.

Optional Reverse Exit

Some tools can reverse back out, saving time and avoiding extra digging.

*Slightly louder near start and end points due to air pressure release, similar to a jackhammer but brief*

Static

Controlled, Precise Pulling

A cone-shaped bursting head is pulled through the old pipe using a powerful rod or cable system.

Breaking and Expansion

As the head moves forward, it splits the old pipe and pushes the debris and soil outward making space for the new pipe.

Hydraulic System

Steel rods or a strong cable are inserted into the old pipe from the pulling shaft, and these rods/cable are connected to the cone-shaped bursting head. A hydraulic pulling unit at the other end applies the tensile (pulling) force, and this force is created by the unit pressurizing fluid to move pistons, which in turn pull the rods or cable outward.

New Pipe in One Pull

The new HDPE pipe is attached behind the bursting head and pulled into place at the same time, with no need to dig up the yard.

Capable of Handling Tough Material

With special attachments, this system can handle both brittle and non-brittle pipes, including steel and ductile iron.

*A much quieter process. Static Pipe Bursting has become more of the modern method of today*

(b) A massive bursting head getting ready for the Static process

For the Decision Makers

Here are some things to consider when making the decision:

Pipe Bursting is an excavation free pipe replacement method used to replace old or damaged underground pipes without having to dig up your entire property.

Instead of removing the old pipe, we break it apart underground using a specialized bursting head while simultaneously pulling a brand new, high-strength HDPE pipe through the same path. (High-Density Polyethylene, rust-resistant)

This is the most effective method for replacing old, failing pipes. On top of keeping your yard, driveway, and business intact and operational, you're guaranteed a lifetime-lasting upgrade that will leave you with peace of mind and stability.

(a) Bursting Head entering and replacing the old pipe by pulling through the new

Pipe Bursting.

Pneumatic

Air Powered Force

Uses compressed air to drive a special hammer that breaks apart the old pipe, piece by piece.

Expander Creates Space

A cone-shaped expander pushes broken fragments and soil outward to make room for the new pipe.

Pulled Through by Winch

A cable keeps the tool centered and steadily pulls the new pipe into place.

Minimal Interruption

Once started, the process continues automatically until the new pipe is fully installed.

Optional Reverse Exit

Some tools can reverse back out, saving time and avoiding extra digging.

*Slightly louder near start and end points due to air pressure release, similar to a jackhammer but brief*

Static

Controlled, Precise Pulling

A cone-shaped bursting head is pulled through the old pipe using a powerful rod or cable system.

Breaking and Expansion

As the head moves forward, it splits the old pipe and pushes the debris and soil outward making space for the new pipe.

Hydraulic System

Steel rods or a strong cable are inserted into the old pipe from the pulling shaft, and these rods/cable are connected to the cone-shaped bursting head. A hydraulic pulling unit at the other end applies the tensile (pulling) force, and this force is created by the unit pressurizing fluid to move pistons, which in turn pull the rods or cable outward.

New Pipe in One Pull

The new HDPE pipe is attached behind the bursting head and pulled into place at the same time, with no need to dig up the yard.

Capable of Handling Tough Material

With special attachments, this system can handle both brittle and non-brittle pipes, including steel and ductile iron.

*A much quieter process. Static Pipe Bursting has become more of the modern method of today*

Static and Pneumatic

Pipe Bursting systems generally fall into two main categories: Pneumatic & Static. To a simplicity, the difference comes down to the how that system breaks the old pipe, and what exactly powers it. Choosing the right method depends on a number of site-specific factors, including the condition and depth of the existing pipe, the type of replacement pipe, the soil type, and how much access is available. Experience, equipment, and risk all come into play when deciding which approach is best.

Air Powered Force

Uses compressed air to drive a special hammer that breaks apart the old pipe, piece by piece.

Expander Creates Space

A cone-shaped expander pushes broken fragments and soil outward to make room for the new pipe.

Pulled Through by Winch

A cable keeps the tool centered and steadily pulls the new pipe into place.

Minimal Interruption

Once started, the process continues automatically until the new pipe is fully installed.

Optional Reverse Exit

Some tools can reverse back out, saving time and avoiding extra digging.

Controlled, Precise Pulling

A cone-shaped bursting head is pulled through the old pipe using a powerful rod or cable system.

Breaking and Expansion

As the head moves forward, it splits the old pipe and pushes the debris and soil outward making space for the new pipe.

Hydraulic System

Steel rods or a strong cable are inserted into the old pipe from the pulling shaft, and these rods/cable are connected to the cone-shaped bursting head. A hydraulic pulling unit at the other end applies the tensile (pulling) force, and this force is created by the unit pressurizing fluid to move pistons, which in turn pull the rods or cable outward.

New Pipe in One Pull

The new HDPE pipe is attached behind the bursting head and pulled into place at the same time, with no need to dig up the yard.

Capable of Handling Tough Material

With special attachments, this system can handle both brittle and non-brittle pipes, including steel and ductile iron.

Static

Controlled, Precise Pulling

A cone-shaped bursting head is pulled through the old pipe using a powerful rod or cable system.

Breaking and Expanding

As the head moves forward, it splits the old pipe and pushes the debris and soil outward making space for the new pipe.

New Pipe in One Pull

The new HDPE pipe is attached behind the bursting head and pulled into place at the same time, with no need to dig up the yard.

Hydraulic System

Steel rods or a strong cable are inserted into the old pipe from the pulling shaft, and these rods/cable are connected to the cone-shaped bursting head. A hydraulic pulling unit at the other end applies the tensile (pulling) force, and this force is created by the unit pressurizing fluid to move pistons, which in turn pull the rods or cable outward.

Capable of Handling Tough Material

As the head moves forward, it splits the old pipe and pushes the debris and soil outward making space for the new pipe.

*A much quieter process. Static Pipe Bursting has become more of the modern method of today*

Pneumatic

Air Powered Force

Uses compressed air to drive a special hammer that breaks apart the old pipe, piece by piece.

Expander Creates Space

A cone-shaped expander pushes broken fragments and soil outward to make room for the new pipe.

Pulled Through By Winch

A cable keeps the tool centered, and steadily pulls the new pipe into place.

Minimal Interruption

Once started, the process continues automatically until the new pipe is fully installed.

Optional Reverse Exit

Some tools can reverse back out, saving time and avoiding extra digging.

Air Powered Force

Uses compressed air to drive a special hammer that breaks apart the old pipe, piece by piece.

Expander Creates Space

A cone-shaped expander pushes broken fragments and soil outward to make room for the new pipe.

Pulled Through By Winch

A cable keeps the tool centered, and steadily pulls the new pipe into place.

Minimal Interruption

Once started, the process continues automatically until the new pipe is fully installed.

Optional Reverse Exit

Some tools can reverse back out, saving time and avoiding extra digging.

Static

Controlled, Precise Pulling

A cone-shaped bursting head is pulled through the old pipe using a powerful rod or cable system.

Breaking and Expanding

As the head moves forward, it splits the old pipe and pushes the debris and soil outward making space for the new pipe.

New Pipe in One Pull

The new HDPE pipe is attached behind the bursting head and pulled into place at the same time, with no need to dig up the yard.

Hydraulic System

Steel rods or a strong cable are inserted into the old pipe from the pulling shaft, and these rods/cable are connected to the cone-shaped bursting head. A hydraulic pulling unit at the other end applies the tensile (pulling) force, and this force is created by the unit pressurizing fluid to move pistons, which in turn pull the rods or cable outward.

Capable of Handling Tough Material

With special attachments, this system can handle both brittle and non-brittle pipes, including steel and ductile iron.

*A much quieter process. Static Pipe Bursting has become more of the modern method of today*

*Slightly louder near start and end points due to air pressure release, similar to a jackhammer but brief*

Pneumatic vs Static

Pipe Bursting systems generally fall into two main categories: Pneumatic & Static. To a simplicity, the difference comes down to the how that system breaks the old pipe, and what exactly powers it. Choosing the right method depends on a number of site-specific factors, including the condition and depth of the existing pipe, the type of replacement pipe, the soil type, and how much access is available. Experience, equipment, and risk all come into play when deciding which approach is best.

Pneumatic vs Static

Pipe Bursting systems generally fall into two main categories: Pneumatic & Static. To a simplicity, the difference comes down to the how that system breaks the old pipe, and what exactly powers it. Choosing the right method depends on a number of site-specific factors, including the condition and depth of the existing pipe, the type of replacement pipe, the soil type, and how much access is available. Experience, equipment, and risk all come into play when deciding which approach is best.

(b) A massive pipe bursting head getting ready for the Static process

(b) A massive bursting head getting ready for the Static process

Pneumatic

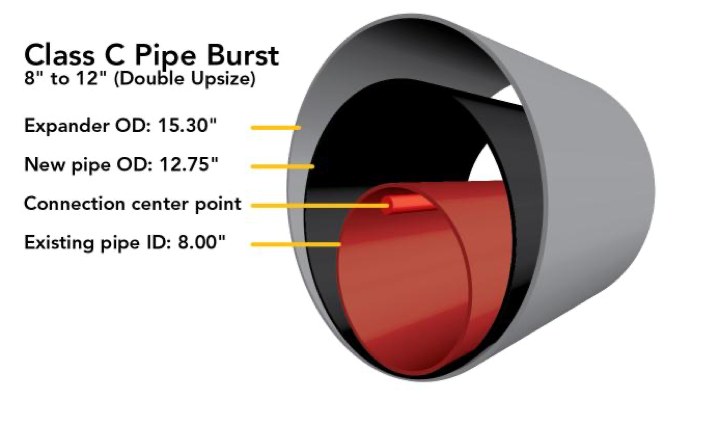

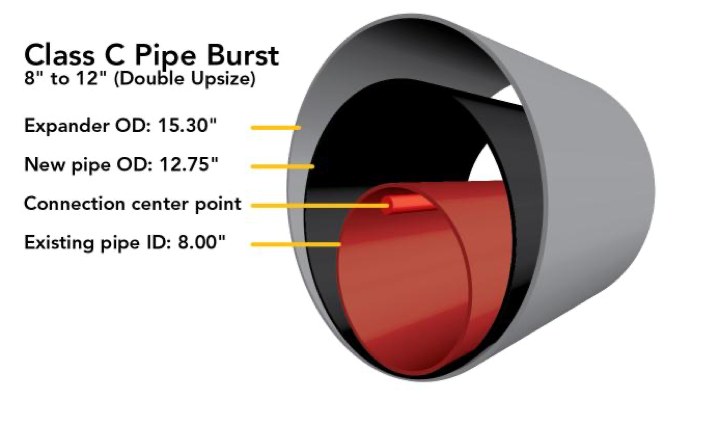

According to the IPBA, International Pipe Bursting Association, pipe bursting has four classifications: A-B-C-D. These classifications are meant to be used as a general guideline in the design and preconstruction phase of an online replacement by pipe bursting. The success of the pipe bursting project is dependent on the qualifications of the project team, geotechnical conditions, existing pipe material and condition,

burst length, depth of pipe, and degree by which the pipe diameter will be increased.

Overall Diameters

*a Triple Upsize would go all the way up to 15" *

Did You Know...

Pipe bursting was first developed in the UK in the late 1970s by D. J. Ryan & Sons in

conjunction with British Gas, for the replacement of small-diameter, 3- and 4-inch cast iron gas mains!

Classifications of Difficulty and Increase of New Pipe Diameter

According to the IPBA, International Pipe Bursting Association, classifies pipe bursting work into four classifications: A-B-C-D. These classifications are meant to be used as a general guideline in the design and preconstruction phase of an online replacement by pipe bursting. The success of the pipe bursting project is dependent on the qualifications of the project team, geotechnical conditions, existing pipe material and condition, burst length, depth of pipe, and degree by which the pipe diameter will be increased.

Classifications of Difficulty and Increase of New Pipe Diameter

According to the IPBA, International Pipe Bursting Association, pipe bursting has four classifications: A-B-C-D. These classifications are meant to be used as a general guideline in the design and preconstruction phase of an online replacement by pipe bursting. The success of the pipe bursting project is dependent on the qualifications of the project team, geotechnical conditions, existing pipe material and condition,

burst length, depth of pipe, and degree by which the pipe diameter will be increased.

Classifications of Difficulty and Increase of New Pipe Diameter

Reconnect & Restore Flow

After we've pulled the pipe through, we hook everything back up to your system and test to make sure water is flowing perfectly.

04

03

Break & Replace

Going through our entry points, a powerful bursting head is pulled through the old pipe, breaking it apart underground. At the same time, a brand new HDPE (High Density Polyethylene) pipe is seamlessly pulled into place behind it.

We start by identifying the damaged pipe using advanced locating tools and inspection cameras. Pure precision.

Locate the Problem

Clean Up & Done

Minimal disruption, a punch-out list, and your new pipe is now stronger, lifetime-lasting, and built to modern standards.

Break & Replace

Going through our entry points, a powerful bursting head is pulled through the old pipe, breaking it apart underground. At the same time, a brand new HDPE (High Density Polyethylene) pipe is seamlessly pulled into place behind it.

Instead of digging up the whole yard, we only need two small entry points: one at the start of the pipe and one at the end.

Break & Replace

Prep Two Access Points

How It Works

01

STEP

Locate the Problem

We start by identifying the damaged pipe using advanced locating tools and inspection cameras. Pure precision.

STEP

02

03

STEP

Break & Replace

Going through our entry points, a powerful bursting head is pulled through the old pipe, breaking it apart underground. At the same time, a brand new HDPE (High Density Polyethylene) pipe is seamlessly pulled into place behind it.

04

STEP

Reconnect & Restore Flow

After we've pulled the pipe through, we hook everything back up to your system and test to make sure water is flowing perfectly.

05

STEP

Clean Up & Done

Minimal disruption, a punch-out list, and your new pipe is now stronger, lifetime-lasting, and built to modern standards.

How It Works

Prep Two Access Points

Instead of digging up the whole yard, we only need two small entry points: one at the start of the pipe and one at the end.

Let's Get In Touch.

Underground Advantage embodies and embellishes every job with the precision and trust that you need. From the first inspection to the final connection, we do the work people are proud to talk about, and when it matters most (which it always does), we're the ones they call.

Reach out for a Free Inspection!

Let's Get In Touch.

Underground Advantage embodies and embellishes every job with the precision and trust that you need. From the first inspection to the final connection, we do the work people are proud to talk about, and when it matters most (which it always does), we're the ones they call.

Reach out for a Free Inspection!

Reconnect & Restore Flow

After we've pulled the pipe through, we hook everything back up to your system and test to make sure water is flowing perfectly.

STEP

05

Clean Up & Done

04

Minimal disruption, no trenches left behind, and your new pipe is stronger, lifetime-lasting, and built to modern standards.

03

Break & Replace

After we've pulled the pipe through, we hook everything back up to your system and test to make sure water is flowing perfectly.